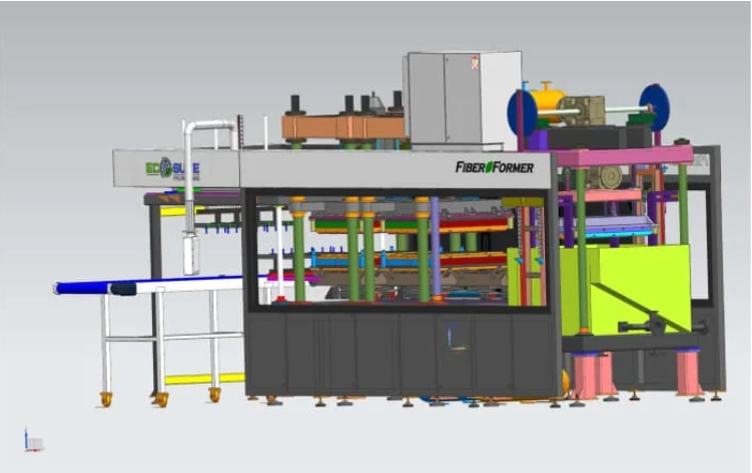

EPTL’s ECOFA series is a next-generation servo-driven FiberFormer machine equipped with a single forming station and single hot press station. This advanced machine is 100% trimming-free and equipped with an automatic counting and stacking system. It is specifically designed for producing high-quality tableware products made from fiber pulp in the form of slurry. The FiberFormer Series utilizes advanced robotics to achieve precise molded products, setting new benchmarks for efficiency and precision.

Designed with advanced engineering for unmatched precision, efficiency, and reliability — setting new benchmarks in fiber pulp molding technology.

| Particular | Fiber Former-9570 | Fiber Former-12085 | Fiber Former-7565 | Fiber Former-160100 |

|---|---|---|---|---|

| Platen Size | 950 × 700 mm | 1200 × 850 mm | 750 × 650 mm | 1600 × 1000 mm |

| Machine Size (L×W×H) FOOT PRINT | 6500 × 1850 × 2800 mm | 6950 × 2100 × 2900 mm | 3500 × 1550 × 3450 mm | 7400 × 2500 × 2900 mm |

| Operation Type | Fully Automatic — Servo Driven | Fully Automatic — Servo Driven | Fully Automatic — Servo Driven | Fully Automatic — Servo Driven |

| Forming Type | Dip Type — Reciprocating | Dip Type — Reciprocating | Rotary Type | Dip Type — Reciprocating |

| Forming Tank Volume | 750 Ltrs | 1250 Ltrs | 350 Ltrs | 1600 Ltrs |

| Forming Tank Level Adjusting | Automatic | Automatic | Automatic | Automatic |

| Product Type | Plates, Bowls, Tray | Meal Tray, Plates | Containers, Cups, Lids | Plates, Trays |

| Forming Mechanism Movement | Interlocked With LVDT | Interlocked With LVDT | Rotary Arrangement | Interlocked With LVDT |

| Heating Type | Electric / Thermic | Electric / Thermic | Electric / Thermic | Electric / Thermic |

| Production | Up to 400 kg/day | Up to 800 kg/day | Up to 300 kg/day | Up to 1000 kg/day |

Fully automatic FiberFormer features highly energy-efficient designs, with all axes driven by servo motors for smooth and precise operation. In contrast, semi-automatic machines operate using hydro-pneumatic cylinders.