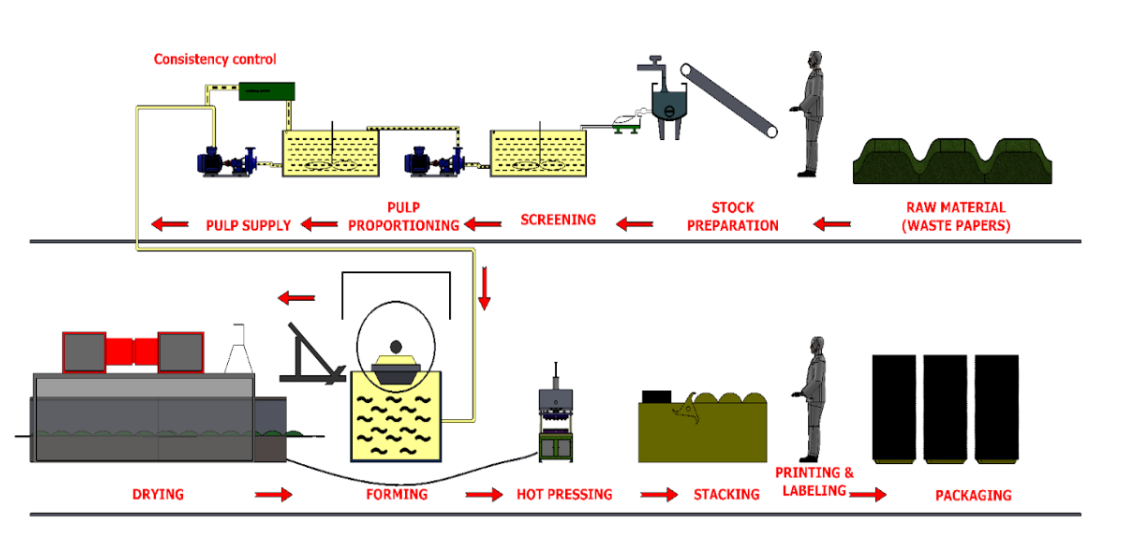

Ecosure Pulpmolding Technologies specializes in advanced industrial packaging solutions that replace traditional plastic and thermocol packaging. Our machines produce durable, biodegradable molded pulp packaging suitable for various industries, including electronics, automotive, and consumer goods.

Utilizes servo-controlled systems for consistent quality.

Compatible with recycled paper, bagasse, and other sustainable fibers.

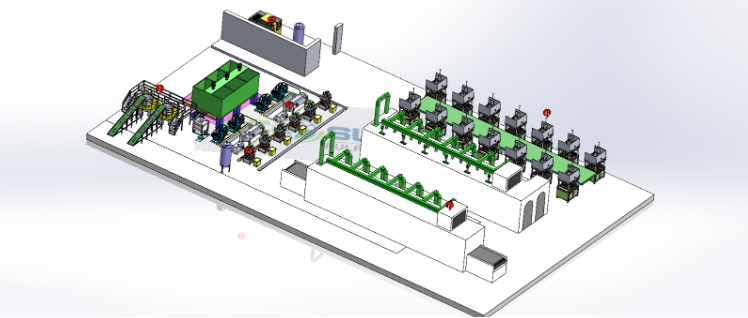

Machines available for capacities ranging from 3 to 30 tons per day.

Easily adaptable to different product sizes and shapes.

Packaging for mobile phones, chargers, and accessories.

Protective packaging for spare parts and components.

Reduces reliance on single-use plastics.

Lower production and material costs.

Tailored solutions to meet specific packaging requirements.