Also known as the Bought-Out Pulp System, this state-of-the-art solution efficiently processes pulp sheets or bales into a uniform pulp slurry.

Maintains precise 0.3% pulp consistency, ensuring consistent downstream operations.

Ideal for biodegradable tableware and sustainable packaging production.

Engineered for reliability and precision for modern manufacturing.

Ecosure Low Consistency Pulper rapidly submerges fiber pulp bales /bundles/sheets/broke which results in reduction on in the slushing time, enhanced efficiency of the pulper and power saving

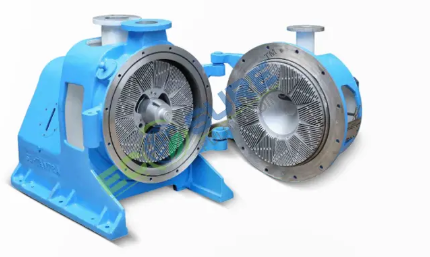

EPTL TDR is improving the slurry beating degree further to produce fine pulp for the agro fiber molding production line. The abrasion section contains two stationary serrated discs on either side of a rotating disc.

Sturdy, latest mechanism, compact, and most important the refiner plates bar designs to specific application in the fiber molding industry. TDR is the result of concentrate precision making this machine exclusive in the agro fiber molding production line.

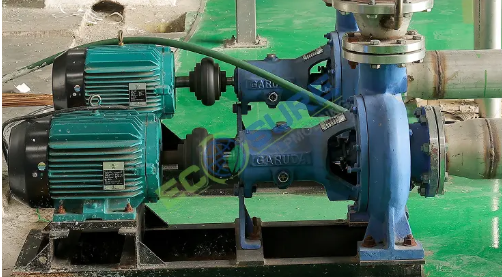

Ecosure Pumps industrial slurry pumps are built for an extensive range of applications including the transfer of slurry/water and backwater generated by our production line.Our non-clog pumps are designed to move slurry, sand, and other materials efficiently and are capable of making suitable pulp for our products. We offer a wide range of models including 3-inch, 4-inch, 6-inch, and 8-inch sizes.

Engineered for durability and high performance, these pumps are constructed from robust, wear-resistant materials to handle the abrasive nature of pulp and slurry. They deliver reliable, consistent flow rates even in challenging industrial environments, reducing maintenance costs and ensuring uninterrupted production.

Our vacuum pump’s main function is to change the pressure in a contained space to create a full or partial vacuum mechanically. Pressure will always try to equalize across connected regions as gas molecules flow from high to low to fill the entire area of that volume.

Therefore, if a new low-pressure space is introduced, gas will naturally flow from the high-pressure area to the new area of low pressure until they are of equal pressure. Notice this vacuum process is created not by “sucking” gases but by pushing molecules.

Our dosing pump sucks a predetermined amount of liquid (OGR, AKD) into the pulp chamber and adds the liquid to a process.The pump is driven by an electric motor or an air actuator and has a controller that turns the pump on and off and manages the flow.

These dosing tanks are designed for precise and efficient liquid handling, ensuring consistent chemical addition to the pulp for optimal process performance. Built from high-quality, corrosion-resistant materials, they offer long-lasting reliability even in harsh industrial environments. The integrated controller allows for accurate flow rate adjustment, minimizing chemical waste and maximizing efficiency.

Our vacuum pump’s main function is to change the pressure in a contained space to create a full or partial vacuum mechanically. Pressure will always try to equalize across connected regions as gas molecules flow from high to low to fill the entire area of that volume.

Therefore, if a new low-pressure space is introduced, gas will naturally flow from the high-pressure area to the new area of low pressure until they are of equal pressure. Notice this vacuum process is created not by “sucking” gases but by pushing molecules.

Our dosing pump sucks a predetermined amount of liquid (OGR, AKD) into the pulp chamber and adds the liquid to a process. The pump is driven by an electric motor or an air actuator and has a controller that turns the pump on and off and manages the flow.

Thermic Fluid Heaters are designed to provide efficient heat transfer for various industrial processes, ensuring precise temperature control and energy efficiency. These systems utilize high-quality thermic fluids to achieve rapid heating with minimal thermal loss, making them ideal for applications requiring consistent, high-temperature performance.

Our panel is specially designed for the pulp molding production line. Our panel can control all equipment on/off automation with minimum manpower interference.

Built with advanced control technology, it ensures seamless integration with various machinery, providing real-time monitoring and precise control over the entire production process. This reduces downtime, enhances operational efficiency, and supports energy-saving initiatives, making it an essential component for modern manufacturing systems.