Turning Used Beverage Cartons into Sustainable Fiber Packaging

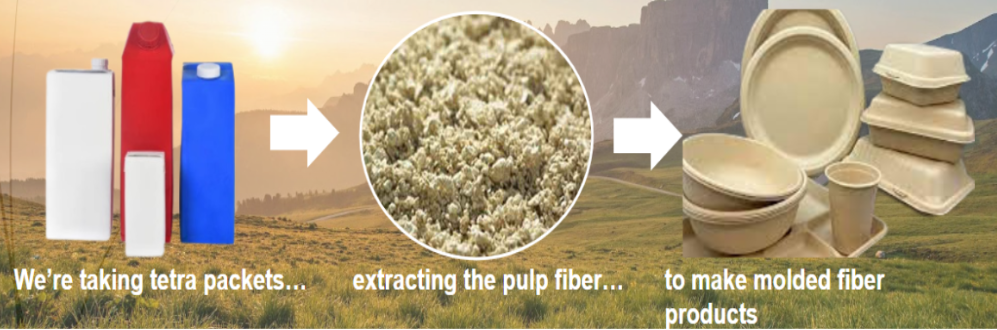

The RECFIB™ Pulp Mill Process is an innovative, patent-pending technology developed to recover valuable cellulose fibers from Used Beverage Cartons (UBC) such as Tetra Pak waste and convert them into sustainable, home-compostable molded fiber packaging.

Our process bridges the gap between waste recovery and eco-friendly packaging by transforming multi-layered packaging waste into a renewable raw material source — giving a second life to post-consumer cartons.

Used beverage cartons (UBCs) are collected, sorted, and shredded into small flakes. These flakes typically contain four layers of paperboard (75%), polyethylene, aluminum, and adhesives.

Using our proprietary hydrapulping and screening system, the paperboard fibers are separated from the plastic and aluminum layers.

The result: clean, high-quality cellulose pulp ready for reuse.

The reclaimed pulp is then used to form eco-friendly molded fiber products such as plates, trays, clamshells, and takeaway containers — that are:

The recovered fiber undergoes refining and cleaning stages to enhance its strength, brightness, and purity, ensuring consistent performance for molded packaging applications.

2–30 Tons Per Day (TPD)

Used Beverage Cartons (UBC)

65–75%

Closed-loop with recycling

Low power consumption optimized for regional utilities

Molded fiber packaging, paper boards, or recycled pulp